Fire Performance

Inherent Fire Resistance

In the case of vinyl products, fire resistance is built into the polymer. Polyvinyl chloride (vinyl or PVC) is formed when chlorine combines with hydrogen and carbon. The chlorine component of the vinyl polymer makes it naturally fire retardant – a distinction between it and all other plastics. Finished vinyl products don’t emit chlorine either.

CHEMICAL FABRICS AND FILM FIRE RESISTANCE Facts

They will resist ignition and slow a fire’s growth, thus helping to increase escape time. Vinyl products can also be formulated to meet a wide range of flame requirements.

Fire resistance makes materials more desirable for certain applications and contributes to the overall durability of chemical fabrics and films. These materials are not only able to be made in a multitude of colors, highly versatile, and easily cleaned, they are long-lasting.

In upholstery and furniture coverings, the main focus of testing is to prevent ignition of the underlying polyurethane foam cushioning, which can be a major contributor to the intensity of the heat and spread of flame. The ease with which chemical fabrics and films can be enhanced with flame retardant properties makes them well suited to these applications.

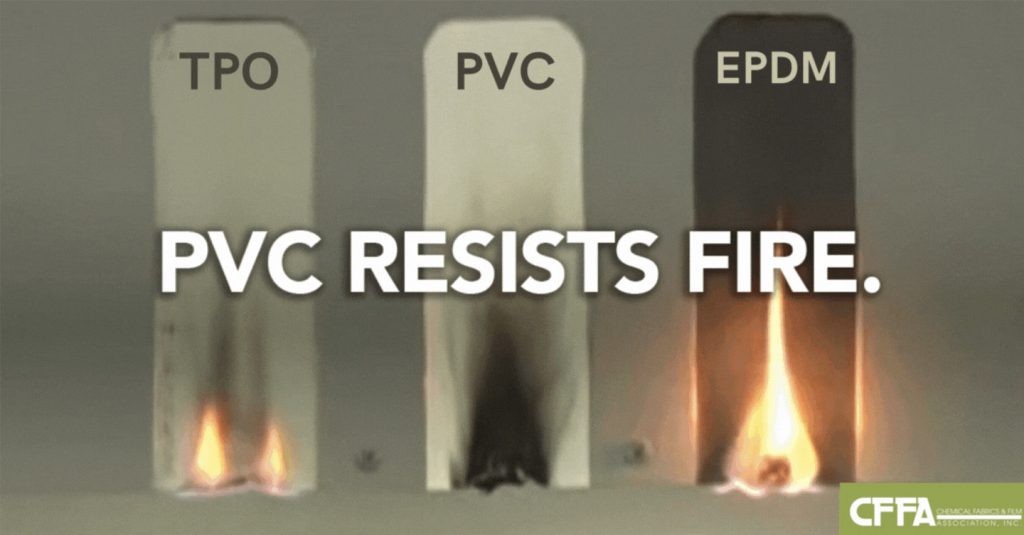

Vinyl roofing membranes are fire resistant.

Vinyl (PVC) roofing membranes are also inherently fire resistant, being slow to catch or spread fire and self-extinguishing when the source of heat or flame is removed. PVC roofs have passed both FM and UL fire testing. This fire resistance is part of vinyl roofing’s overall durability. Also, its heat-welded seams form a permanent, watertight bond that is a major advantage over commercial roofing systems that rely on adhesives, tapes, and caulks to seal the seams. It meets or exceeds wind uplift requirements, with many PVC membranes surviving the onslaught of hurricanes.